THROUGH-

HOLE

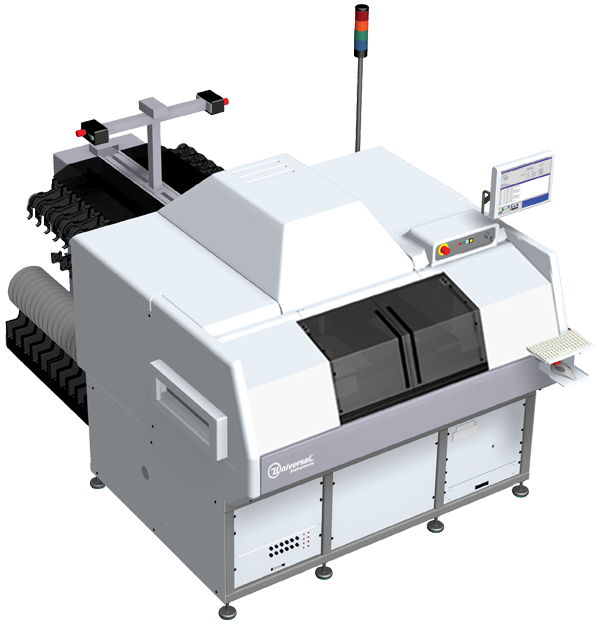

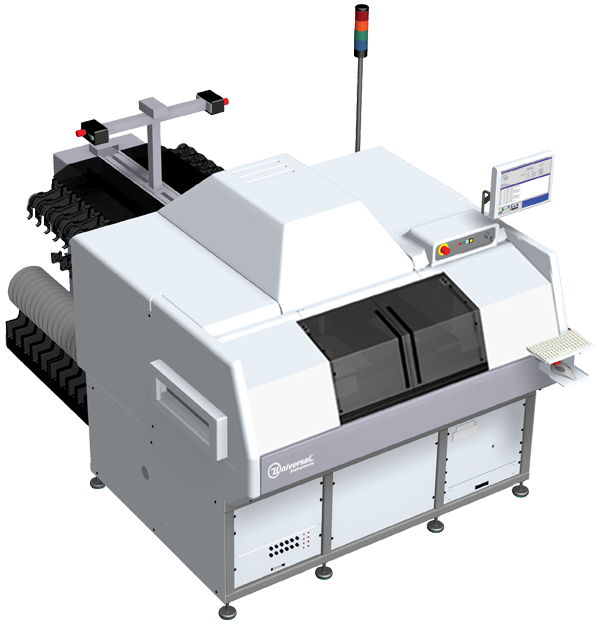

RADIAL 88HTi

The Radial 88HTi brings a new level of productivity to radial component sequencing and insertion, offering consistently high throughput regardless of component type.

vcd 88HTi

The VCD 88HTi combines established reliability, 220 input stations, and the highest throughput rates in the industry for fast, efficient sequencing and insertion of axial components and jumper wires in one process.

jumper wire 88

The Jumper Wire 88 inserts wire from bulk input packages at rates up to 32,500cph, while maintaining an outgoing board quality of 75ppm or better.

radial 88hti

The Radial 88HTi offers consistently high throughput regardless of component type, with single-, dual-, triple-, and quad-span insertion variants. Lead span capability up to 10mm virtually eliminates tedious manual assembly requirements to improve throughput, product quality and output per floor space, while reducing associated labor costs and time requirements to provide greater returns. The Radial 88HTi delivers exceptional flexibility with over 100 available inputs on the expandable sequencer. An intuitive operator interface that is common with other Generation 88HT equipment offers easy operation, diagnostics, data management and a graphical product editor.

- 22,000 CPH

- Highest reliability in the industry (300 ppm)

- Component replenishment without machine stoppage

- Manual Load or Automatic PCB Load/Unload

- Configurable sequencer (In-Line or Straight-Back)

- Multiple clinch options

- Component Verifier

- Simple-to-use operator environment with graphical user interface

Hidden Toggle

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

RADIAL 88HTi MODELS & SPECS

- Radial 88HT Single-Span – 2.5mm

- Radial 88HT Dual-Span – 2.5/5.0mm

- Radial 88HT Triple-Span – 2.5/5.0/7.5mm

- Radial 88HT Quad-Span – 2.5/5.0/7.5/10.0mm

Real Throughput (cph)

Radial 88HTi

Insertion Directions

Radial 88HTi

(1° inc)

Insertion Pitch

Radial 88HTi

2.5, 5.0

2.5, 5.0, 7.5

2.5, 5.0, 10.0

2.5, 5.0, 7.5, 10.0

Clinch Options

Radial 88HTi

90 Long

90 Short

(prog height)

Component Supply

Radial 88HTi

Board Handling

Radial 88HTi

Load/Unload

Radial 88HTi

2 sec

(pass-through)

Component Inputs

Radial 88HTi

Sequencer Styles

Radial 88HTi

vcd 88hti

For single-process sequencing and insertion of axial components and jumper wires, the VCD 88HTi delivers reliable productivity at the highest throughput rates in the industry. An error rate of less than 200 ppm is the result of Universal Instruments’ enduring lineage of through-hole development and leadership. Component changeover is minimized with over 220 available inputs on the expandable sequencer. An intuitive operator interface that is common with other Generation 88HTi equipment offers easy operation, diagnostics, data management and a graphical product editor.

- 24,500 CPH

- Highest “real” throughput axial sequencer/inserter

- Highest reliability in the industry (200 ppm)

- Component replenishment without machine stoppage

- Expandable from 20 inputs up to 220 inputs

- Manual Load or Automatic PCB Load/Unload

- Component Verifier

- Simple-to-use operator environment with graphical interface

Hidden Toggle

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

VCD 88HTi MODELS & SPECS

- High-Density: 5.00–22.02mm

- High-Reliability: 7.62–22.48 (optional kit up to 24.00mm)

- Large Lead: 7.62–21.77mm

Real Throughput (cph)

VCD 88HTi

Insertion Directions

VCD 88HTi

Insertion Span (mm)

VCD 88HTi

Clinch Angle

VCD 88HTi

(prog height)

Component Supply

VCD 88HTi

Ammo Pack

Reel

Note: Can mix ammo packs and reels in any position

Defect Rate

VCD 88HTi

Load/Unload

VCD 88HTi

2 sec

(pass-through)

Component Inputs

VCD 88HTi

jumper wire 88

The Jumper Wire 88 inserts wire from bulk input packages into printed circuit boards with the flexibility to handle a wide range of wire spans without changing tooling. Exceptional outgoing board quality levels of 75ppm or better with high insertion speeds and zero wire scrap deliver superior price performance and yields. An intuitive operator interface that is common with other Universal Through-Hole equipment offers easy operation, diagnostics, data management and a graphical product editor.

- 33,000 CPH

- Zero Scrap – zero scrap leads

- Highest reliability in the industry (75 ppm)

- Programmable clinch angles 25° to 75° from vertical

- Manual Load or Automatic PCB Load/Unload

- Simple-to-use operator environment

- 5 to 33mm spans

Hidden Toggle

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

JUMPER WIRE 88 MODELS & SPECS

- Standard: 5.0–33.0mm

Real Throughput (cph)

Jumper Wire 88

Insertion Directions

Jumper Wire 88

Insertion Span (mm)

Jumper Wire 88

Clinch Angle

Jumper Wire 88

(prog height)

Component Supply

Jumper Wire 88

0.51 mm to 0.81 mm

Defect Rate

Jumper Wire 88

Load/Unload

Jumper Wire 88

2 sec

(pass-through)