September 30, 2014 – Component packaging is the single most important issue to take into account when considering automation for odd-form factor components. The electronics industry is pretty unique in that the majority of components are regulated by a third-party organization. These organizations recommend and control the parameters for the majority of the conditions and structure of an electronic device.

The name “odd-form” is relative to the unusual configuration of a device, but moreover denotes that the device is not really bound to any specific standard, and therefore manufacturers are free to offer the device in any form factor and in any transportation media.

The most popular odd-form component package is none… Bulk pack is used far too often and generally causes damage in transportation from the manufacturer to the end user. Some devices are suitable for bulk packaging, but mostly those that do not have wire leads.

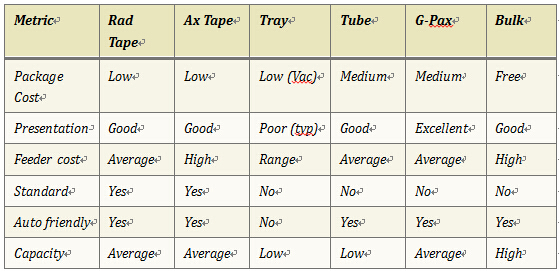

When weighing the benefits of different package types, there are many factors to consider for shipping, cost and volume of the component within package itself. If you are considering automation for labor savings, the worst thing that you can do is to have a low-volume package that requires a high attention rate at the manufacturing tool.

As a general rule, we submit the following chart as a reference for the different types of packaging. Six types of component packaging (Radial Tape, Axial Tape, Tray, Tube, G-Pax and Bulk) are compared in terms of Package Cost, Package Presentation, Feeder Cost, Standardization, Automation Friendliness and Package Capacity. While this chart does not provide empirical data for decision making, it does provide a thumbnail view of the different styles and the general outcome.

At the end of the day, the best package will provide a viable shipping media as well as deliver components to the assembly machine in a substantial volume and in the best mechanical condition.

If you find this article helpful and would like to know more, you may contact Stan Earley (Marketing Manager of Automation Solutions in Universal Instruments) by +1-607-725-5129 or earleys@uic.com. You can also go to our website https://www.uic.com/solutions/automation/ for more information on Automation.