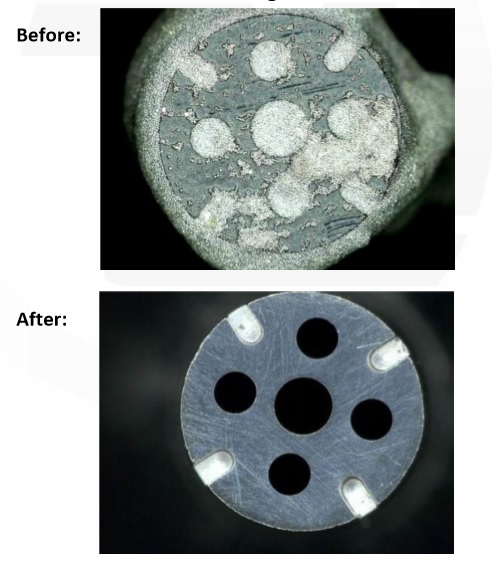

One of the most critical steps to a robust SMT process is having clean nozzles.

No SMT equipment can place components accurately and run efficiently without well-maintained nozzles. If the machine is either unable to pick parts consistently or hold on to the components during the transport from feeder to PCB, defects will result. An increase in defects means a decrease in production! Proper nozzle maintenance is critical for optimal placement productivity.

Are you experiencing any of the following placement problems?

Miss-picks OR

Skewed placements

Then you may have dirty or contaminated nozzles, which require maintenance.