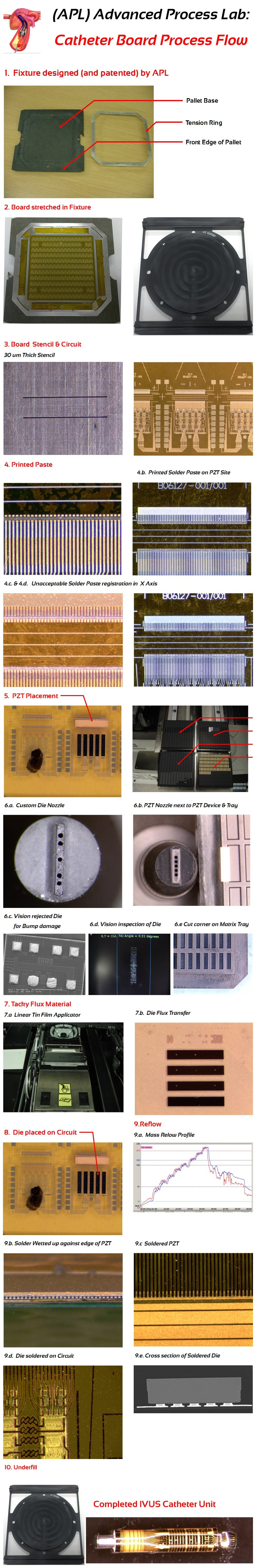

August 18, 2014 – Universal Instruments is going to hold a China market-focused seminar at NEPCON Shenzhen on August 26 & 27, in Rose Hall #2, 5th floor, Shenzhen Convention Center, and the Advanced Process Laboratory (APL) will present the precise and robust process for a leading-edge heart catheter circuit board. To sign up for this presentation,

For more information about the Advanced Process Laboratory (APL), go to http://www.uic-apl.com/home or contact David Vicari via vicari@uic.com/+1 607-779-5151.