[section background_repeat=”repeat” background_position=”center top” background_attachment=”static” background_scroll=”none”]

January 27, 2015 – With so many placement head design concepts available, how do you tell which one is the best? The answer lies in the anatomy of the placement head. Whether it’s rotary, inline, small or large, each has its unique characteristics.

Rotary head provides a higher level of parallel processing and usually relies on fewer mission critical assemblies (less redundancy and overall cost of ownership), leading to higher overall reliability. One of the most advantageous attributes however is the lack of dependency on “gang picking” of components to realize top speeds.

There are several iterations of rotary heads as well taking advantage of these concepts, ranging from horizontal, to vertical, to even “tilted”. Traditional horizontal “turrets” have size limitations tied directly to component range that impact the diameter of the turret and can result in tradeoffs regarding PCB placement area reach. Many manufacturers have sacrificed component range for overall machine size (dedicating their products to small PCB sizes and limiting each modules component range).

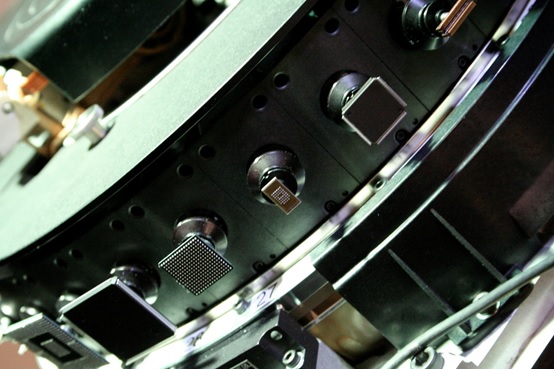

It is possible, however, to approach a perfect balance. Vertical style turret sizes provide less PCB “footprint” while still providing the best in class advantages of single pick/place points, greater parallel processing and greater spindle to spindle independence. To maximize the true potential of this design, other variables must be considered. How many spindles are optimal? What is the spacing of the spindles (directly relates to turret diameter)? How does this impact PCB placement area, and lastly how do I drive this system in PHI, but also in X,Y, and Z?

In order to provide the greatest amount of flexibility, the quantity of spindles and spindle-to-spindle spacing is a consideration. Some manufacturers choose to broaden their component range by “skipping adjacent spindles when handling larger parts. Others afford a full range for all spindles. To provide a flexible component range, vision is also a key factor. You can sacrifice resolution (MpP), or you can utilize multiple systems on the head to provide the optimal capabilities for various ranges of components. Dual on-the-head cameras systems are perfect solution. The ability to have this broad component range leads to easier line balancing for drastically different PCB designs as well as the capability to sustain the highest placement rates possible, with very little derate.

Interestingly enough, as the vertical turret grows, so does its ability to populate larger PCB sizes. This ultimately leads to the fastest placer for all PCB sizes, rather than a dedicated and small range.

This abundance of spindles also helps facilitate a maximum duty cycle, and improved amortization of components gathered for each “task block” versus the travel to and from the feeders and placement area.

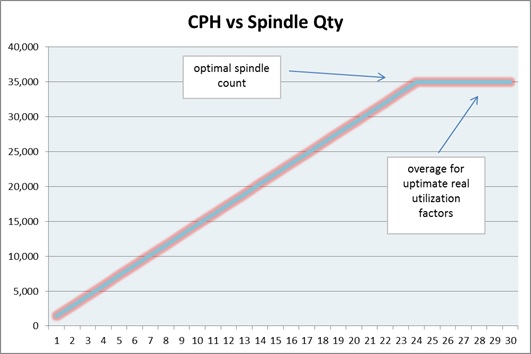

A comparison of spindle quantity to realized throughput grows linearly at first, but then begins to asymptotically approach maximum speed at an optimal count. There is always room for margin though. By adding a couple of extra spindles, maximum speed is still achieved, while also providing supplemental capacity to cover dedicated spindles/nozzles (specialty components like MELFs, connectors, etc.), or potentially bypassed spindles (damage, contamination detection, etc.). This leads to higher overall utilizations and lower MTBA.

Not all placement heads are the same, and not all take advantage of the physics behind each concept’s strengths to deliver the ultimate in speed, flexibility and overall performance.

For more information on Universal Instruments’ Surface Mount solutions, visit https://www.uic.com/solutions/surface-mount/ or contact Todd Vick (+1 607-768-1633/vickt@uic.com).

[/section]